Sustainable Environment

Influence your Environmental Sustainability Report

Novum Energy Australia Pty Ltd is all about innovation – it’s about applying technology, in an environmentally green space, addressing pollution and converting excessive rubber-based waste to renewable energy sources and other high-quality by-products.

This scenario is not so much about the technology; it’s a tool to create value in developing regions where economic “dynamos” are still required to produce jobs, energy and development. In first world countries end-of-life rubber waste is a symptom of a consumer’s society.

Rubber used in the mining and construction industries (i.e. tyres, conveyor belting, rubber screens, flexible hose and rubber tracks) is deemed to be an ideal supply in producing socio-economic benefits.

The next generation solution converts carbon-based feedstock to re-usable products and renewable energy with minimal waste. Due to the precision of the process, products are of the highest quality, and the carbon black can be utilised in the manufacture of new tyres, rubber componentry, PVC piping, and Polyethylene pipe re-using end-of-life tyres to make new tyres.

On site distillation of renewable fuel feedstock to produce light and heavy oil derivatives to meet demand, and the potential to generate (combined fuel source) up to 2Mw of renewable energy for local consumption or grid connection, adding to the renewable electricity market and syngas production.

Diversion from landfill to high-quality re-usable products presents significant benefits for communities and authorities.

Managing our environment

Emissions Testing

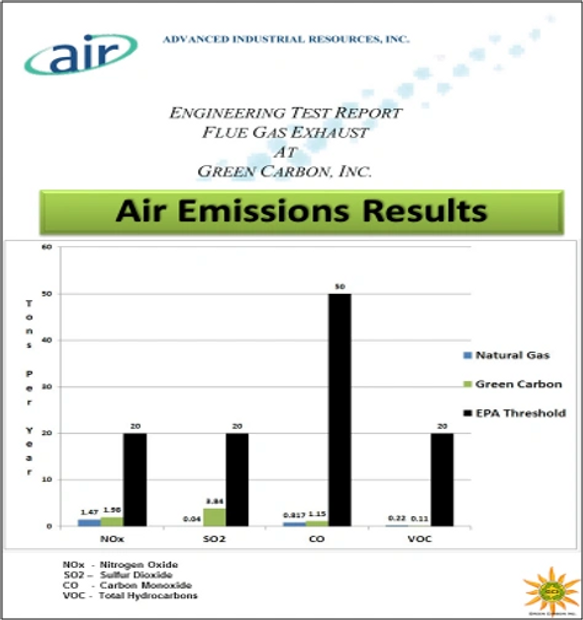

Emission testing of facilities in the USA & Canada result in levels substantially below the EPA threshold. The TVR process is a proven environmentally friendly option for managing rubber waste - with the ability to convert to reclaimable carbon based products.

Tyre Recycling - Reclaimable Carbon

- The bulk of rubber around the world is headed for landfill - Novum Energy Australia want to change this direction and reclaim / re-use as much carbon as possible - starting with the largest tyres (OTR) utilised in the mining sector. Countries like Chile are starting to legislate to improve the re-use of rubber.

What is Chilean Law No. 20.920?

- Law of Waste Management, Extended Producer Responsibility and Promotion of Recycling.

- Although enacted in May 2016, implementation meetings are just now being held to establish goals for collection and recovery. EPR is intended to provide a circular recycling model for waste management by creating a system where the producers or importers are responsible for organizing and financing waste management.

Renewables Fuels - Generation

- Called a Bio-cogeneration System, Green Carbon’s Thermal Vacuum Reactor System utilises a custom designed generator produced by Caterpillar to capture a synthetic gas by-product of the recycling to power the generator.

- “We were looking for a way to use the excess gas that is produced in the system in an environmentally friendly way,” said Green Carbon co-founder Phil Wilson. “I approached not only Caterpillar, but several other companies and Caterpillar was the one that was able to develop the generator so that it would work off our gas.”

- The generator is a variation of one of Caterpillar’s existing generators, adapted to burn the off-gas from Green Carbon’s process.